- Home Page

- ECC Books

- ECC Reliability Database

- ECC Projects

- Consulting Services

- News 2023

- Products

- Contact

- Papers

- Partners

- ECC Academy 2024

- Career Coaching

- ECC Team

My journey Around the World

December

Pero – Milano (Italy), Ulm Wiblingen (Germany) – December 18th, 2019

TECSA S.r.l. is proud to announce that it has signed a new partnership agreement with ECC, to provide integrated safety and reliability consultancy services worldwide.

"One of the key challenges for all industries across the globe is to integrate the reliability engineering program with safety engineering program along with the product life. Therefore, we are delighted to announce this strategic partnership with Tecsa s.r.l., which aims to support the industry to provide products with a high level of safety, integrity, and reliability,”

said Dr.Eduardo Calixto, CEO of ECC.

"The partnership with ECC is the latest achievement of TECSA S.r.l.",

said Dr. Luca Fiorentini, Executive Director of TECSA S.r.l..

“Integrating safety and reliability is strategic to deliver high-quality consultancy services which combine with the most modern holistic safety management systems, thus creating new value from the comprehensive approach, progressively adopted by a significant number of companies operating in different industrial sectors.”

Automatic Historical Reliability Database

You do not need to use more reliability generic database ! The integrity PRO reliability 4.0 solution enable to produce an online reliability database based on your own equipment failure data. The advantage of automatic reliability database 4.0 are:

- Reliability database based on your own equipment data;

- Online reliability data available for all users;

- To compare the reliability performance for different equipment;

- Reliable input data for maintenance, logistic reliability and safety studies;

- No need to use MTTF and Failure rate.

Please read the paper below

Distance learning Program 2020 for process and Oil and Gas Industry

the best seller book " gas and oil reliability engineering : modeling and analysis" in online training format explained by the author dr eduardo calixto

Distance learning Program 2020 for Railway Industry

THE BOOK " RAMS and LCC for railway industry: Analysis, MODELING AND OPTIMISATION" IN ONLINE TRAINING FORMAT EXPLAINED BY THE AUTHOR DR EDUARDO CALIXTO

Euromaintenance 2021

As a member of EFNMS, I have the pleasure to announce the Euromaintenance 2021. The Website is already on. Go to link to get information about sponsorship, Exhibition and more.

November

15° Congresso Nacional de Manutencao em Braga, Portugal nos dias 21th-22th November 2019.

ECC será expositora no 15° Congresso Nacional de Manutencao em BRAGA, Portugal nos dias 21 e 22 de Novembro de 2019. Visite nosso estande para saber as novidades de nossos produtos e servicos (https://lnkd.in/dg8EiQU). Tambem apresentaremos o tema : Revolucao da Confiabilidade 4.0 como parte da gestao de ativos físicos: Um estudo de caso aplicado a industria de Petróleo e Gás.

ECC will be exhibitor at 15° National Maintenance Congress at Braga, Portugal on 21th-22th November 2019. Please visit our stand to know the news about our services and products. We will also present: "Reliability 4.0 Revolution as part of Facility Management: The Oil and Gas Platform case study.

October 2019

ECC Presential Online training 2019 for process industry

ECC is proposing the Presential Online training for everyone who were not able to attend the ECC training in 2019.

Dr. Eduardo Calixto will deliver the whole training online in a virtual class. The attendees will be able to follow the training by webex access. In the end of each model it will be open to question. The investment for this training is also lower and you save also with trip cost. The training planned for October, November and December are:

- RAM Analysis for Process and Oil and Gas Industry 24th-25th October 2019

- Asset Management for Process and Oil and Gas Industry 28th-29th November2019

- Risk Management and Analysis Methods for Process and Oil and Gas Industry 2nd-3th December 2019

ECC Training Calendar 2020 for Process Industry

ECC training calendar for 2020 is already in our website. The wonderful news is that we will provide our 2020 training in USA with support of our Partner McNally LCC - Machinery Reliability

Solutions (http://mcnally-llc.com/).

We will also provide training in Germany, Turkey, UEA, Singapur, Malaysia, Indonesia.

ECC Training Calendar 2020 for Railway Industry

ECC training calendar for Railway Industry 2020 is already in our website. The wonderful news is that we will provide our 2020 training in Australia and Japan

We will also provide training in Germany and UK as well as the Inhouse training for companies based on their request.

September 2019

The RCM is the first step of Maintenance Plan that starts in design phase: What´s the Journey from RCM to Asset Management maintenance plan?

ECC training 2019: RAM analysis for process and Oil and Gas Industry at 17th -18th October Istanbul, Turkey.

August 2019

How to predict the future failures of aged asset during decommissioning phase ?

Asset management applied to Building Facilities methodology

July 2019

Case1 -RAM analysis applied during design phase: The Oil platform case study

One of the most important decision during a Oil and Gas platform design phase is to define the Platform configuration to define the level of redundancy and reliability requirement for the critical equipment. In addition, it´s very important to consider the preventive maintenance influence in platform reliability equipment ´s performance. Please find attached the complete paper.

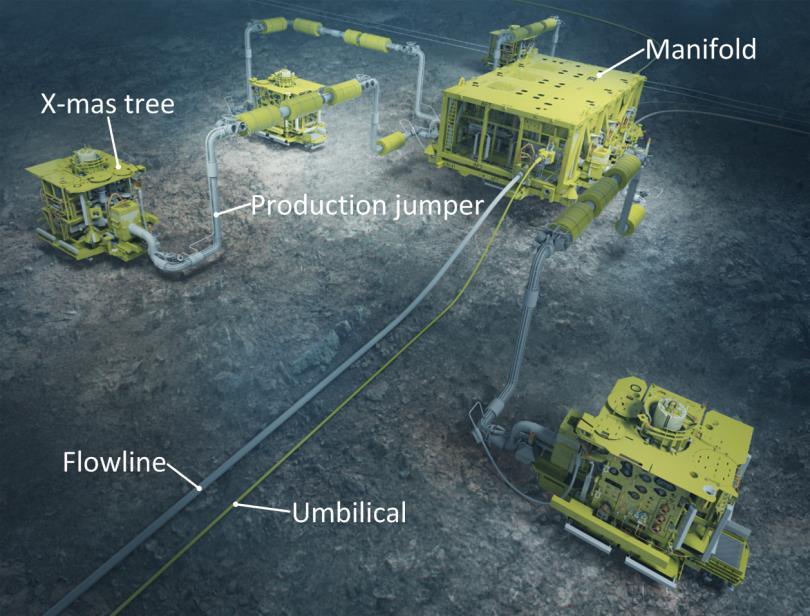

Case 2 -RAM Analysis applied for Subsea system Maintenance and spare part optimization

In order to support the asset high performance achievement throughout the life cycle the paper will demonstrate the optimization methodology based on Dynamic Programming Algorithm integrated to the apmOptimizer software which enable to predict the asset performance, such as production efficiency, operational availability, reliability and also take into account the asset configuration, maintenance, inspection policies to minimize the life cycle cost.

Please check the RAM analysis presentation below

June 2019

RAM Analysis training for Process Industry: 12th and 13th August 2019, Munich, Germany.(Language: English)

The RAM analysis is applied to whatever physical asset and the main objectives are:

1 - To predict the System/equipment/component performance such as production Efficiency, operational availability, reliability, expected number of failures, expected number of Preventive maintenance, expected number of inspection, Life cycle cost.

2 - To identify the system critical equipment and/or equipment critical component and their impact on system/ equipment operational availability and reliability.

3 - To predict future system performance based on planned plants modifications, different spare part policies, different preventive maintenance plan.

4 - To Analyse the impact of the spare part policy in the system performance (operational availability)

5 - To Analyse the impact for preventive maintenance in the system performance (operational availability)

6 - To define the optimum time to perform preventive maintenance concerning the impact of life cycle cost and performance (operational availability)

7 - To define the system configuration during design (level of redundancy vs reliability target).

8 - To define the equipment reliability target to enable the system to achieve the reliability target. That is the basis for the warranty contract with equipment vendors.

PS: Go to the link below to check the ECC training calendar in Germany

RAM Analysis training: 19th - 20th August, Vienna, Austria (Language: English)

The RAM analysis is applied to whatever physical asset and the main objectives are:

1 - To predict the System/equipment/component performance such as production Efficiency, operational availability, reliability, expected number of failures, expected number of Preventive maintenance, expected number of inspection, Life cycle cost.

2 - To identify the system critical equipment and/or equipment critical component and their impact on system/ equipment operational availability and reliability.

3 - To predict future system performance based on planned plants modifications, different spare part policies, different preventive maintenance plan.

4 - To Analyse the impact of the spare part policy in the system performance (operational availability)

5 - To Analyse the impact for preventive maintenance in the system performance (operational availability)

6 - To define the optimum time to perform preventive maintenance concerning the impact of life cycle cost and performance (operational availability)

7 - To define the system configuration during design (level of redundancy vs reliability target).

8 - To define the equipment reliability target to enable the system to achieve the reliability target. That is the basis for the warranty contract with equipment vendors.

PS: Go to the link below to check the ECC training calendar in Austria

Prognostic Health Management (PHM) based on AI solution for railway applications

The Prognostic Health Management (PHM) aims to prevent such corrective action, incident and accident by monitoring the physical asset condition and alert in case of physical asset deterioration or degradation stage. Such methodology relies on sensor information input as the basis of the prognostic. Therefore, PHM had the advantage to provide constant health conditions state about the physical asset rather than the schedule preventive maintenance or NDT that also detect the physical asset degradation, but in a specific period of time.

Based on Artificial Intelligence (AI) concept, it´s important to have a PHM that´s is adaptative to the new data collected by sensors along time and enable to update the health condition prediction based on pre-defined algorithm.

The PHM based on AI is a very good solution to prevent incidents and new technologies have been developed in the last five years that looks very promisor for the near future for different industries such as railway as shows the figure 1.

Basically, the PHM system presented in figure 1 encompasses two rugged RotoSense wireless sensor modules packaged for standard mounting on the wheels of a rail car or locomotive axle, one Sentinel Gateway wireless data collection hub, to collect and store RotoSense data and the RailSafe Toolbox, including the necessary software packages to set up and operate the RotoSense sensors and the Sentinel Gateway, and to extract and display diagnostic and prognostic information based on RotoSense data.

The sensors are mounted on each end of an axle, right where the wheels and track meet, the three-dimensioned microelectromechanical systems (MEMS)-based instruments continuously capture wheel and track vibration data with maximum sensitivity.

Finally, the data are analysed using the RailSafe Toolbox, including the Adaptive Remaining Useful Life Estimator™ (ARULE™), which has been proven in aerospace and industrial condition-based maintenance (CBM) systems.

The PHM relies on sensor information input as the basis of the prognostic, which has some application limitation in the case of rolling stock in the railway industry such as the vision-based and multi-camera high speed imaging unit to take multiple images of every brake shoe for inspection and measurement., which is limited by the train velocity.

ECC website now is translated to five languages to easier understanding from our Partners and Clients

Think always in Reliability First !

Reliability First ! Please go to the ECC website link to understand the RAM Program implementation steps and methods before to implement The asset management program.

ECC become member of the Swiss Association of Facility-Management (fmpro)

ECC in Switzerland since 2018:

In 2018/2019 ECC support Hünnemeyer Consulting to implement the Integrated Logistic Support program concerning different reliability and maintenance methods such as RBD, FTA, FMEA, MAintenance analysis. Such method were implemented for all critical train system. ECC focus on Bogie, Pneumatic System, Fire Protection System and Passenger Information System.

ECC become member of the Maintenance and Facility Society of Austria (MFA)

ECC in Austria since 2016:

- In 2016/2017 ECC supported Molinari Railway (in Schwaz) with the APU (Auxiliary Power Unit) RAMS program for 1000 APU for Locomotive in India Railway.

- In 208/2019 ECC supported AMST in Ranshofen by review the RAMS Program for the Flight Simulator product and defined the improvement actions to be implemented.

May 2019

ECC is very proud to have as a new Partner The SGE in Dubai.

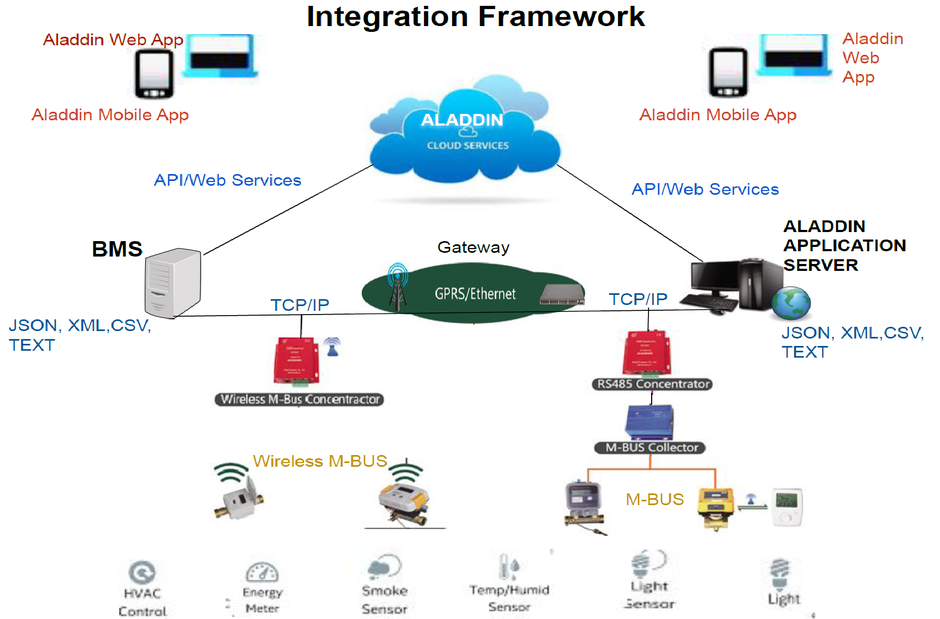

The SGE is the designer of the Aladdin Software solution for Maintenance Management. ECC will provide the Aladdin across the globe for all potential client interested to managed a group of asset easily and efficiently. The Aladdin has been applied sucessfully for Management the maintenance of physical assets Utilities such as Hotels, Shopping, Hospitals, Airports and other build facilities. It can also be applied for different industries such as aerospace, railway, oil and gas and process.

April 2019

ECC is very proud for the results of Indonesia Maintenance 4.0 in Jakarta Indonesia

March 2019

SMRP Solution Magazine: January 2019

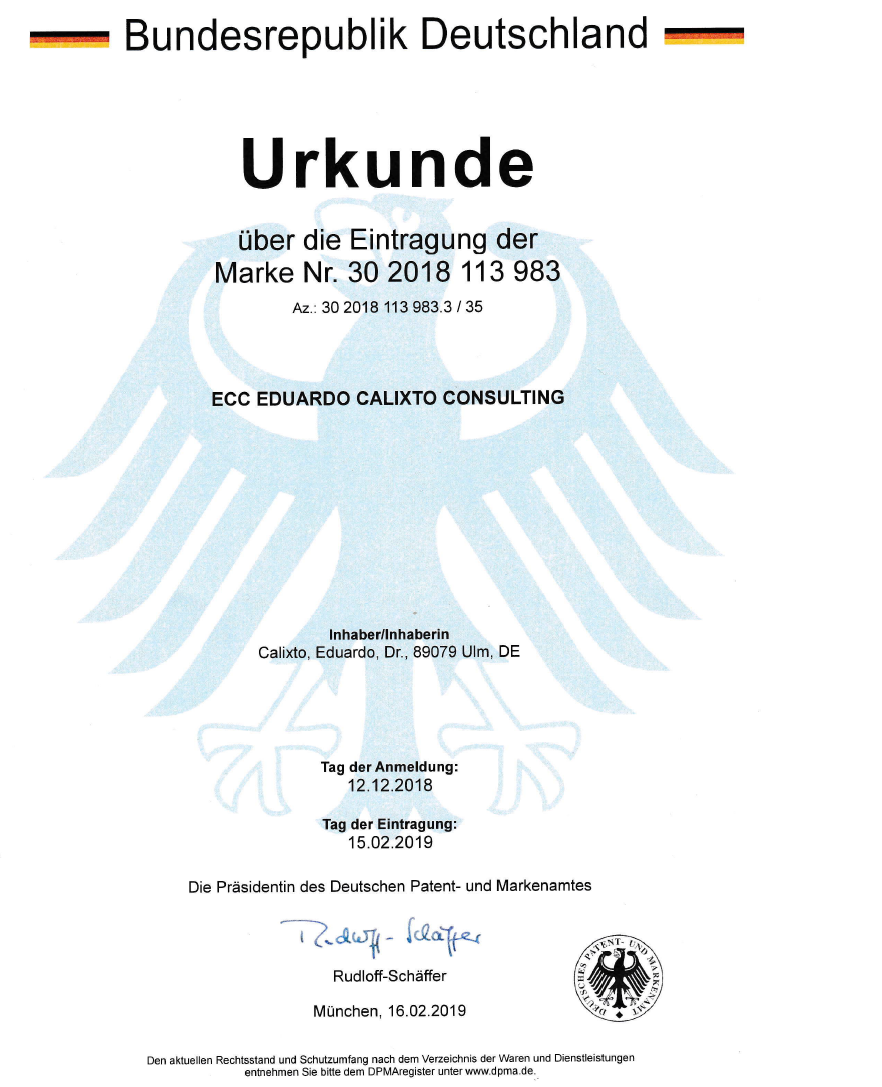

ECC now has the patent of all material published in our website, books, training material, logo and company name

February 2019

ECC is very proud to support the RAMS program Implementation for the Flight Simulator System

January 2019

ECC has a pleasure to deliver the first in House training for railway Industry in China.

Together with our Partner Qinda technology in China, We started our first project in China in 2019. The Project objective is to support the RAMS program implementation. The first step was to deliver 40 hour training including RAMS program, FMEA, Life Time Data Analysis and RAM analysis. The next step is to review the current RAMS procedures and deliver new procedures.